For large construction projects, many variables have to be considered to ensure that the workmanship is of the required standard, and is delivered on time within the specified budget. However, there are several challenges that the site supervisor or the contractor faces while working towards the timely completion of the project, and most notably is the moisture-related problems. It is for this reason that the regulation of humidity levels in a site is crucial for the success of any construction project.

What Does Humidity Level Mean For A Construction Site?

Generally, humidity levels will be higher in the warmer region than in cooler areas, making building sites more difficult to work in. Also, the time of the year and weather pattern can contribute significantly to this. For example, high humidity is frequently observed during thunderstorms. With this, the rain will increase the humidity at a building site.

However, the first step in keeping a building site’s humidity under control is to keep a close eye on the weather. With this, humidity levels may be maintained at acceptable levels on a building site after construction experts recognize the temperature changes and seasonal trends that impact a place.

How High Humidity Level Affect Construction Site

There are various ways high humidity can affect construction sites and personal items. Damage from high humidity levels (over 60% relative humidity) can occur when materials are left in the open for an extended time, even if there is no real contact with water. However, many studies point to the fact that humidity is detrimental to the success and sustainability of any construction in the following ways:

Material Degradation

Different construction materials require specific temperature and humidity conditions under which they can be stored. For instance, manufacturers recommend that cement and grout be stored in cool and dry places that are free from moisture. That is because these materials can absorb moisture from the environment (they are hygroscopic) which may trigger chemical reactions. As a result, they may end up having lower strengths, which eventually compromises the integrity of structural components.

Similarly, exposure of steel reinforcement bars and metallic formwork to moisture may result in corrosion.

Reduced Strength of Structures

High humidity levels may prevent concrete structures from reaching their target strength. When the surrounding moisture is high, the concrete takes more time to dry out, since the surrounding air is not able to hold more moisture. As a result, the overall compressive strength of the freshly placed concrete will decrease significantly.

Apart from that, there is evidence that points to the fact that high humidity increases the pH of concrete. Since concrete is acidic, a shift in pH may interfere with the mixability of any additives or admixtures added to it.

Delayed Construction Period

High relative humidity reduces the rate at which concrete sets and cures. This means that the time required for strength gain will be more. As a result, there will be many downtimes and a high risk of falling behind schedule. For instance, painting the walls may not be possible if the concrete finishes are still wet. Consequently, there will be a loss of labor, which eventually increases the overall cost of the project.

Future Mold Problems

With an increase in moisture, there is a corresponding increase in the probability of mold growth. When relative humidity increases above 55%, there is an increased risk of mold growth both on the construction materials and the constructed surfaces. If immediate control protocols are not initiated, the mold may continue to grow and spread. That is hazardous since it is known to produce spores, which are allergens that may cause respiratory complications to individuals within the site, and future beneficiaries of the project.

Even though the influence of weather in determining environmental humidity may be out of your control, there are alternative means which may be useful in controlling moisture within the site.

How To Low Humidity Level Affects Construction Site

Construction workers will have to lower the site’s humidity under high humidity levels. This will keep mold at bay, keep employees safe from respiratory difficulties, and keep materials from warping. It also fastens the building process since some construction materials take longer to set up in moist circumstances than in dry settings.

However, there is a limit to low humidity on a construction site. This can cause fracture and shrinkage in materials due to dry air. Dry air is usually chilly, but it may be reasonably warm in some places of the United States. So, maintaining adequate humidity levels at a site necessitates different approaches based on the site’s location and climatic conditions.

On the other hand, some construction workers may require heaters on a cold construction site. Exterior building sites can benefit from heat to minimize humidity, particularly during seasons when snow and moisture are a concern. Moisture evaporates due to the heat, allowing construction materials to remain dry.

Finding the Ideal Balance in Humidity Level

According to the Environmental Protection Agency (EPA), the recommended indoor relative humidity level is between 30 and 50 percent. Mould and material degradation are less likely to occur if building sites are kept within this temperature and humidity range. As a rule of thumb, the ideal relative humidity level should be between 30 and 40 for cooler temperatures and 40 to 50 for warmer ones. However, with the many types and brands of dehumidifiers out there, it is vital to seek expert advice from trusted manufacturers and dealers, who may give you the best recommendation depending on your regional climatic conditions and the type of construction you are erecting.

Taking Control of Site Humidity With Dehumidifiers

A proven way to regulate humidity on the construction site is using dehumidifiers. Essentially, these are devices used to control moisture. Depending on your preference, you can select from one of the four categories:

Heat Pump Dehumidifier

These dehumidifiers consist of fans, heat exchange coils, and heat pumps. The fan drives warm moist air to the heat exchange coils. These coils have extremely low temperatures, and when the moist air comes to contact with them, the moisture cools, condenses, and accumulates in a condensation tank.

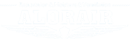

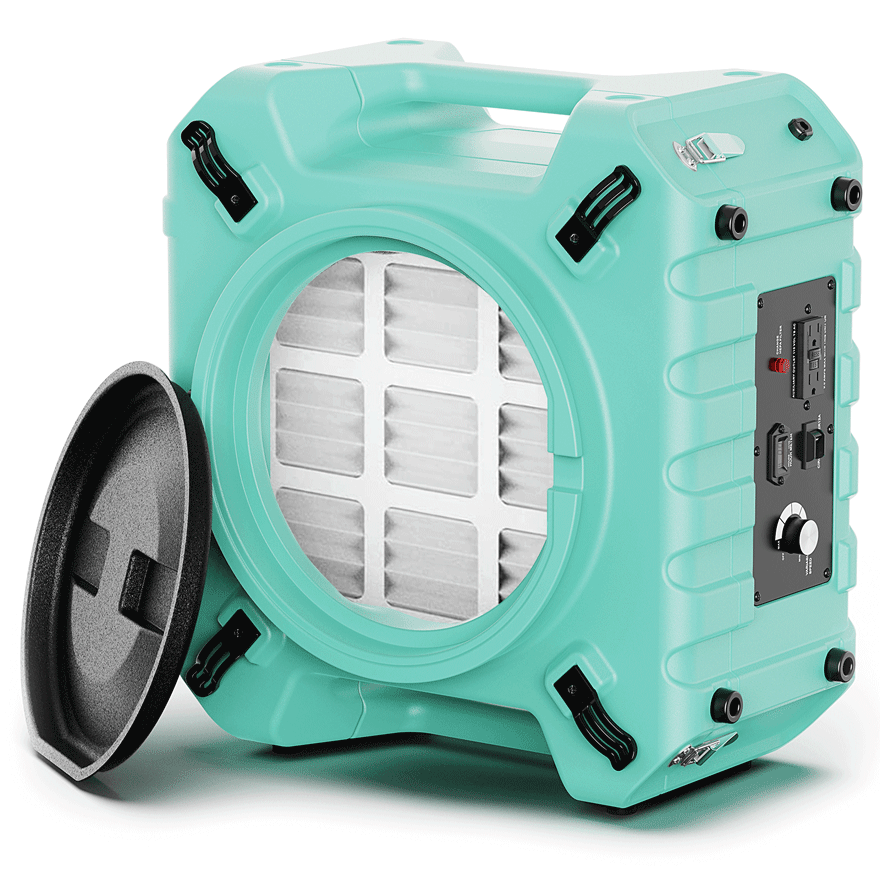

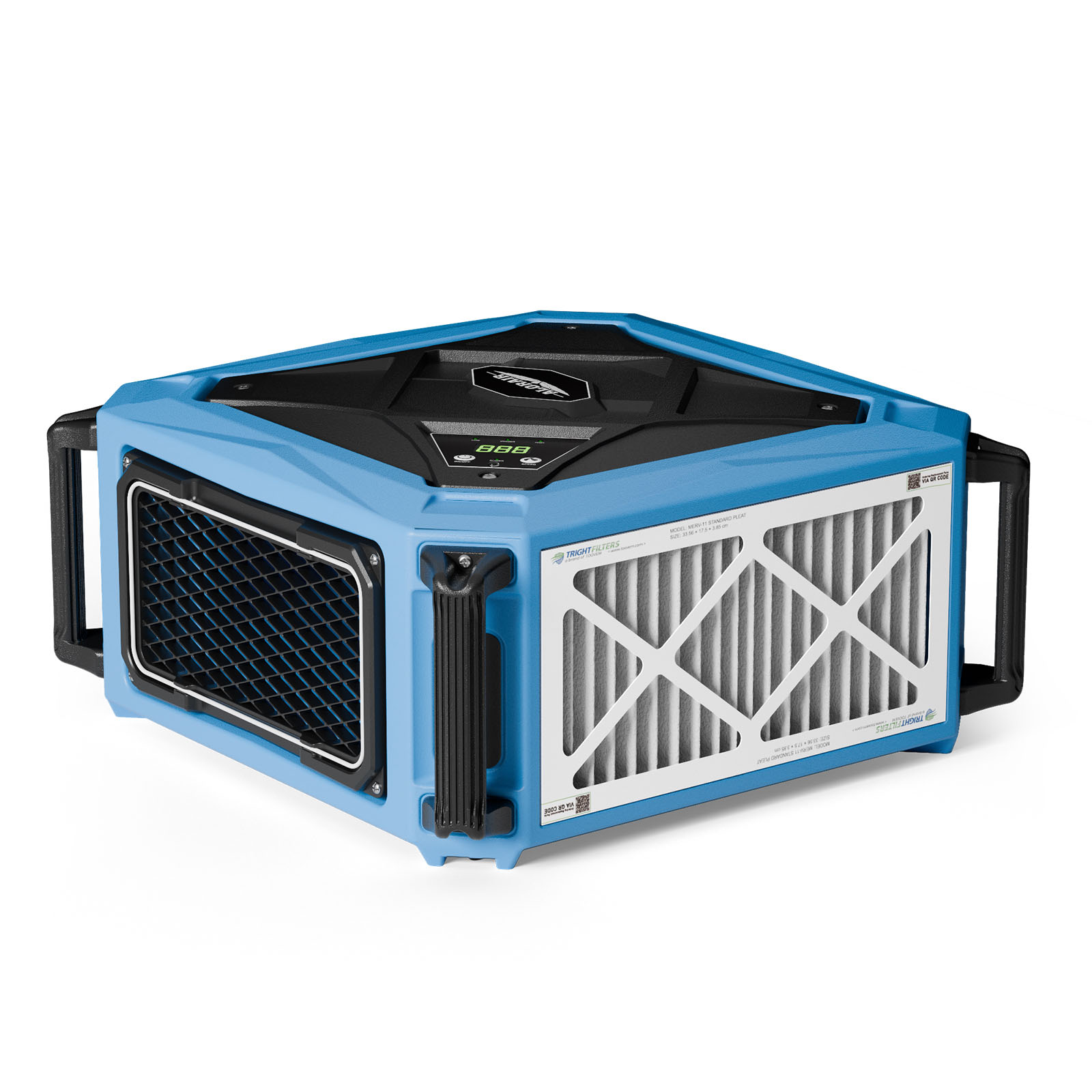

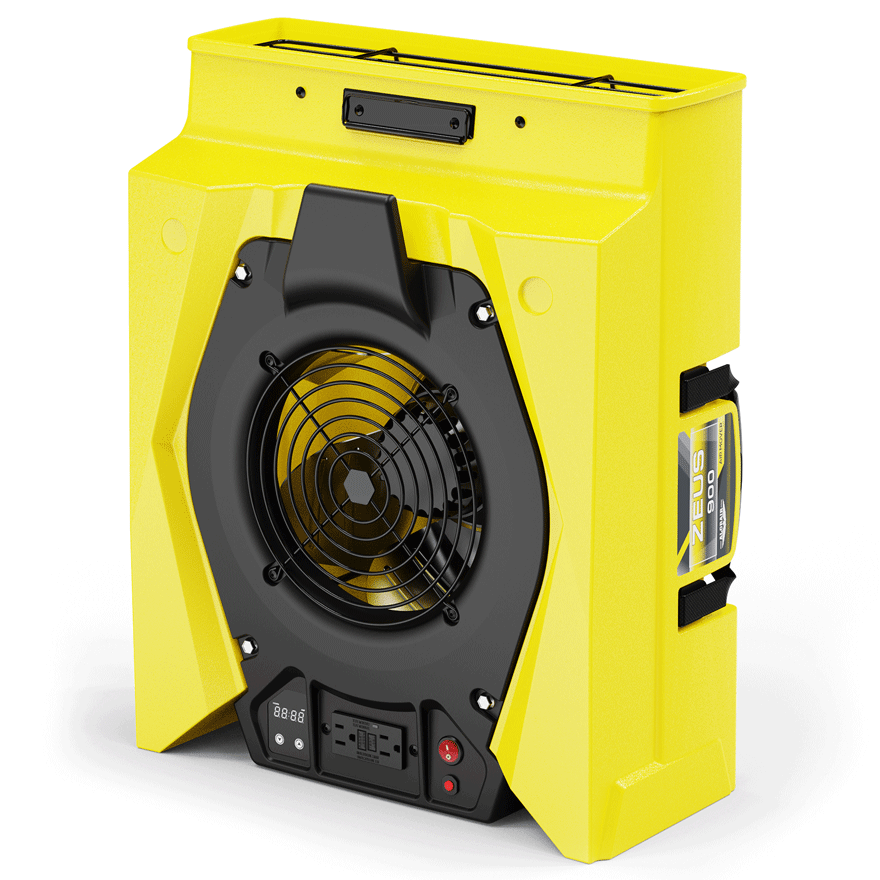

Air Movers

Air movers are used to removing moisture by accelerating the rate of moisture evaporation. It works by increasing the frequency of air circulation. As a result, the drying time on surfaces decreases. It is also known as commercial blower fans, industrial blowers, or floor drying fans.

The dehumidifier is the ideal type to use for moisture control and restoration purposes on a construction site.

Desiccant Dehumidifiers

Desiccant Dehumidifier is a special type of dehumidifier, which does not have compressors or heat exchange coils. Instead, it has a desiccant wheel made of silica gel or any other adsorbent material. The moisture removal process involves the absorption of moisture, and when the hydrophilic material becomes saturated, they are regenerated by internal heaters.

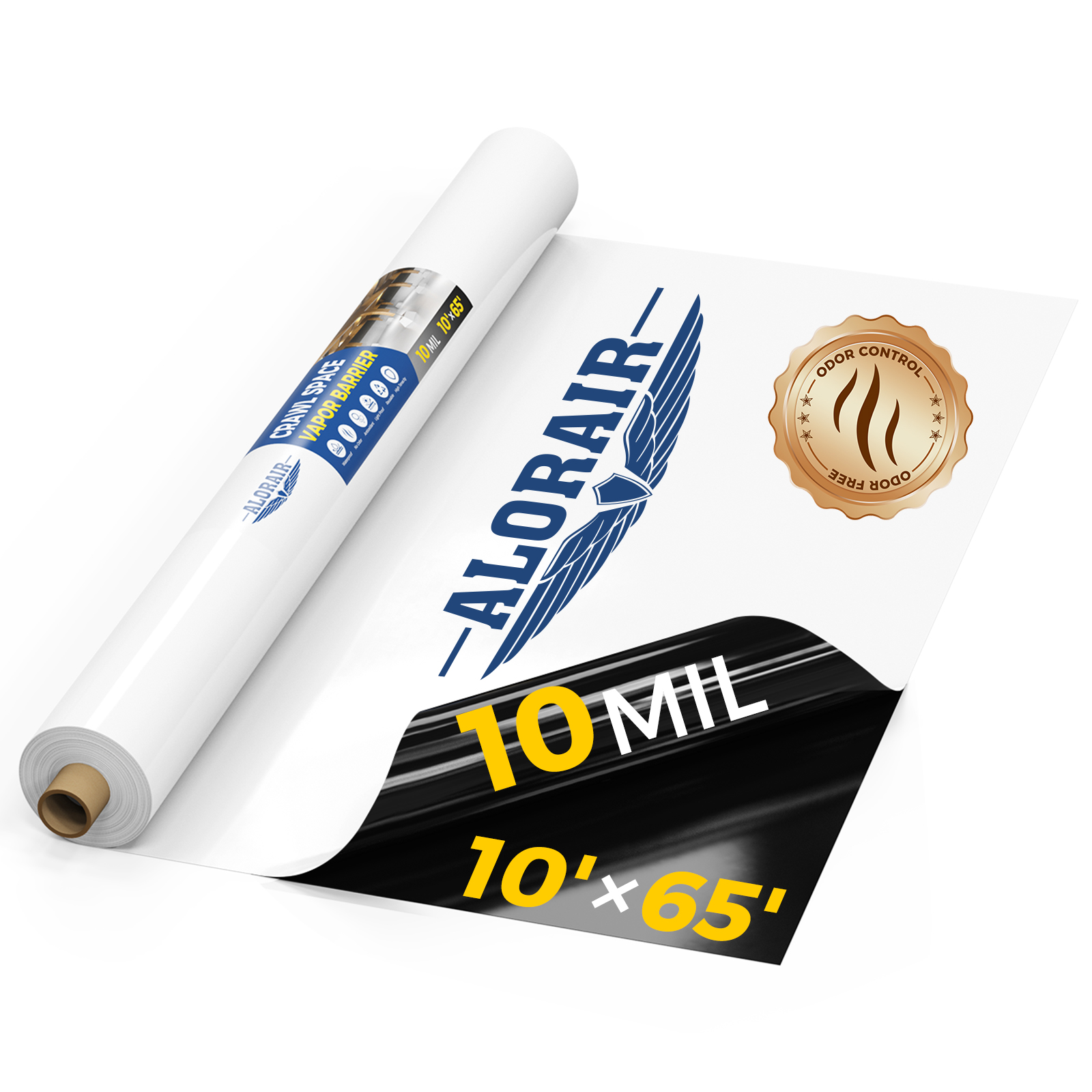

Your Trusted Go-To Suppliers For Dehumidifiers

Are you searching for a trusted dehumidifier to keep your constructions in working condition? Look no further than ALORAIR. We are your best bet at shopping for an affordable dehumidifier for construction sites. No matter your construction work scope, you are assured that our selection will have you pick the right choice for your project.

.jpg)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions