For woodworkers, dust removal is a key aspect of keeping a workspace clean and safe. For small workshops, choosing the right dust collector is critical to effectively capturing and containing airborne dust particles. With countless options on the market, finding the perfect dust collector for your needs can be overwhelming. In this guide, we’ll walk you through the key factors to consider when purchasing a small shop dust collector, ensuring you make an informed decision.

The importance of dust removal in small woodworking workshops

Capture dust is important in woodworking for a number of reasons. First, it helps improve air quality by removing airborne pollutants such as fine dust and other particulate matter, making the air safer to breathe. This can make working in the store more enjoyable and improve overall health and safety. In addition, dust control helps to reduce noise levels and keep the workshop clean. These systems work by taking contaminated air and passing it through a series of filters. The filtered air is then vented back into the workshop, leaving behind the pollutants. This process is repeated continuously, providing a continuous supply of clean air to the workshop.

The basics of dust removal

Extracting dust from the air requires diverting the air from the source of contamination to a dust collecting system. And at a high rate prevents particles from falling and accumulating near the machine. That’s why most air filtration systems use airflow rates measured in cubic feet per minute (CFM) to compare overall filter power.

While CFM is a key measure of system performance, actual performance is often derived from:

• Machine horsepower

• Canister filter captures lower micron particles than the bag filter

• Total cubic feet per minute

• Number of connections for single or dual machines

• Filter rate

• Brand reputation

Also, as you probably know, each tool produces different types of dust or wood chips in different ways. This means that the best dust collector for each tool may vary:

Table saws are best used with a high CFM air filtration system because the open space of the table saw requires more air volume.

Planer work has a concentrated suction and requires a large dust collector, preferably with cyclone action to separate the wood chips.

A drum sander works best with a canister collector, which is more likely to capture fine dust particles.

Small hand tools will perform better with dust extractors since they are designed for random orbit sanders, joinery machines and similar equipment.

Wood saws require a wood saw hood and high CFM to pull suspended dust.

Airflow Capability

Airflow capacity, measured in cubic feet per minute (CFM), is one of the most critical factors to consider. It determines how effectively the dust collector draws dust from the tools and maintains proper airflow in the workshop. For small workshops, a dust collector with an airflow capacity of 500 CFM to 1,500 CFM is usually sufficient. Keep in mind that higher CFM values generally result in better dust collection performance, but you should strike a balance based on your specific needs and the size of your workshop.

Filtering System

Filtration systems play a vital role in capturing and containing dust particles. Look for a dust collector with a high-efficiency filtration system to ensure clean air in your workshop. Two-stage filtration systems are common in dust collectors and include a pre-filter to capture larger particles and a fine filter (such as a HEPA filter) to capture finer dust. This combination provides optimal dust separation and cleaner air quality. Ensure filters are easily accessible and replaceable for hassle-free maintenance.

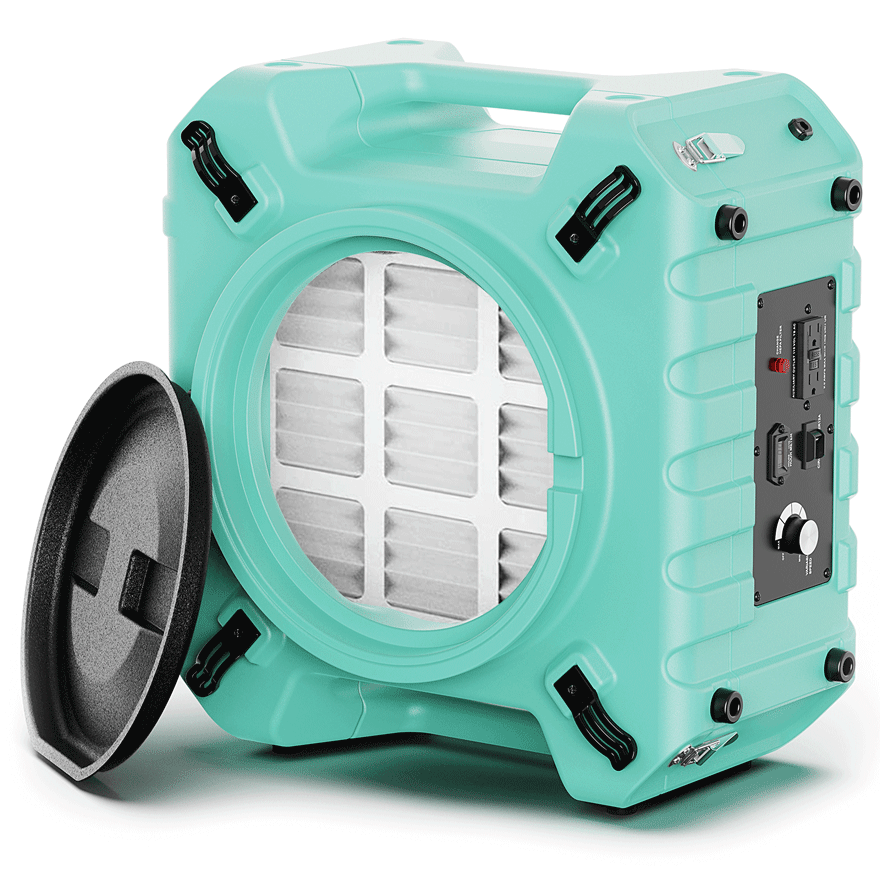

The Puricare 500 uses a 5-micron pre-filter and a 1-micron internal filter to effectively filter tiny particles from the air. And both filters can be easily disassembled and cleaned, which is convenient for you to replace and reuse.

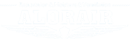

Portability and Space

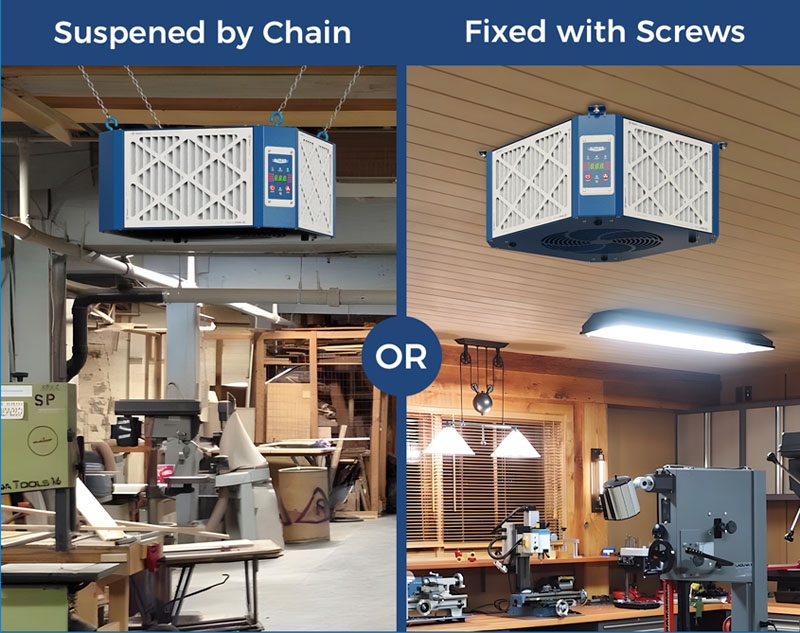

Consider the size and portability of your dust collector, as space is often limited in small workshops. Look for a compact model that is easy to maneuver and fits your store layout. A portable dust collector with wheels makes it easy to move the unit when needed. Also, evaluate models with mounting options, such as wall-mounted, to optimize space utilization in your workshop. The PureCare 1350 dust collector is more effective since it has a 360 degree air intake mechanism. And with its compact size, you can hang the machine from the ceiling with the included eyebolts or fix it on the wall with M4 screws.

Noise Level

Noise can be a big factor, especially if you value a quiet and comfortable work environment. A low-noise dust collector ensures less disturbance during woodworking. Look for models that are specifically designed with noise-canceling features, or consider purchasing noise-canceling headphones to further reduce noise levels. Noise-canceling headphones are also good for mechanical noise blocking when you don’t have the dust collector on.

Build Quality and Durability

Investing in a durable dust collector ensures that it can handle the demands of regular use in a shop environment. Look for models made of sturdy materials that can withstand the rigors of woodworking. Also, consider the warranty provided by the manufacturer as an indicator of product quality and reliability. Generally, the longer the warranty period, the more confident the manufacturer is about the quality of the products he produces.

Budget Considerations

Set a budget for your dust collectors purchase by considering your specific requirements and available funds. Purisystem’s dust collectors are designed for small carpentry workshops, sanding, and sawing activities. In comparison to larger dust collection systems, they are very competitively priced and easy to operate. While finding a cost-effective solution is critical, remember that quality and performance should not be sacrificed to save money. Find a dust collector that balances affordability with meeting your needs.

Conclusions

Choosing the right workshop dust collector for your small space is critical to maintaining a clean and safe woodworking environment. By considering factors such as airflow capacity, filtration system, portability, noise level, build quality, and budget, you can make an informed decision. Take the time to research different models, read customer reviews, and compare specifications to find the dust collector that fits your needs and ensures effective dust removal for your small workshop. Investing in the right dust collector will contribute to a healthier, more enjoyable woodworking experience.

.jpg)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions