What is the effect of humidity? First, the humidity can cause corrosion. Metal rusts when it comes in contact with water. For example, The corrosion of steel begins when the humidity reaches 40% and then accelerates.

Secondly, Mold and hygiene problems can arise. A moist environment is the best place to grow mold and bacteria. Especially in the food industry, in order to ensure the health and safety of consumers, all food must be kept in the humidity of 30-50%, with no bacterial growth environment.

In addition, humidity can do harm to manufacturing machinery. For example, in the beer production process, the mechanical processing process will lead to the change of hot and cold air, the inevitable generation of steam. When a large amount of water vapor continues to cover the surface of the machine or the connecting pipe, the machine is bound to be damaged.

What’s more, humidity can affect the quality of products. The pharmaceutical industry, in particular, has a direct bearing on consumer health. Therefore, the need to control the humidity is very accurate, and the humidity level must be controlled at about 50%, otherwise, the product hygroscopic, reduce the quality of the product.

The traditional way is using heating and ventilation to solve the humidity issue.

Heating can deal with moisture because the high temperature can hold more water, so the relative humidity is low. We also need to pay more attention to the sensitive material in winter because the condensation appears in the low temperature. Some factories use heating to reduce condensation. However, this is not an effective method. In contrast, using heat to dehumidify is expensive. Therefore, using heating to maintain the humidity isn’t a sustainable approach. In addition, if the space lacks insulation, the heat will escape.

Ventilation is also a traditional dehumidification method, widely used in the past dehumidification environment. Ventilation works by increasing airflow so that it is less likely to settle and condense. But the use of ventilation is not an excellent solution to the problem of humidity is inconsistent, uncontrolled, unconditional. Because, even on a well-ventilated day, the air being ventilated has almost the same humidity as the air entering the space.

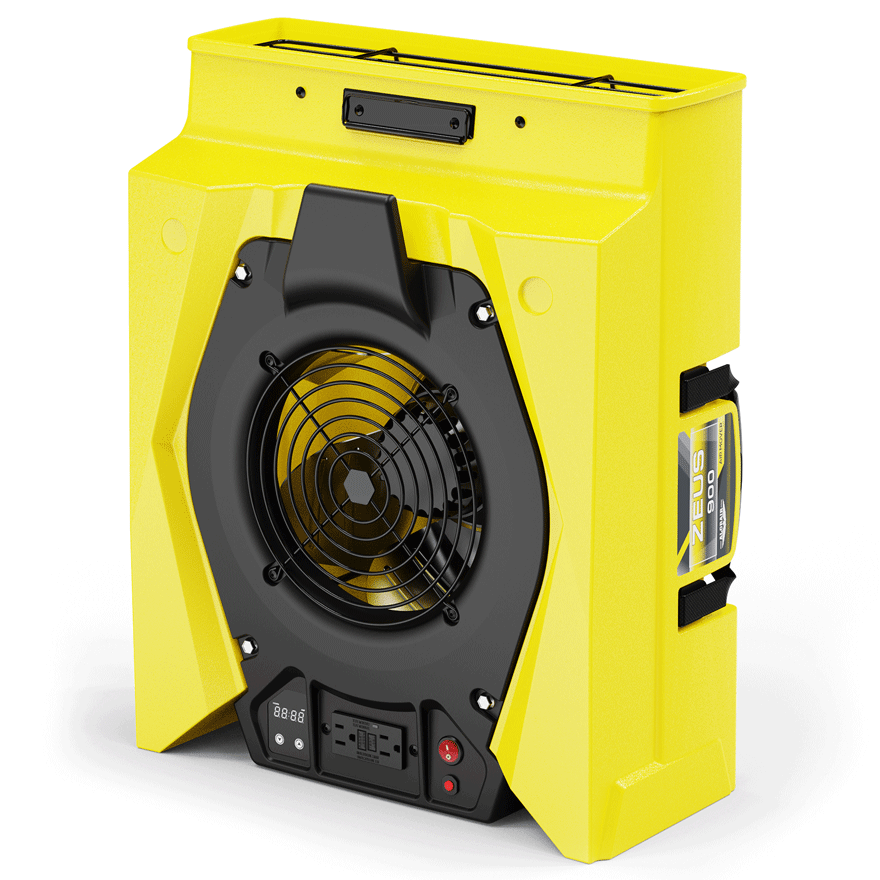

Heating and ventilation can make people feel more comfortable, but they can not apply to the machine and material. Using a commercial dehumidifier is the most effective way to tackle the humidity, and it can apply in various industries.

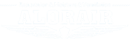

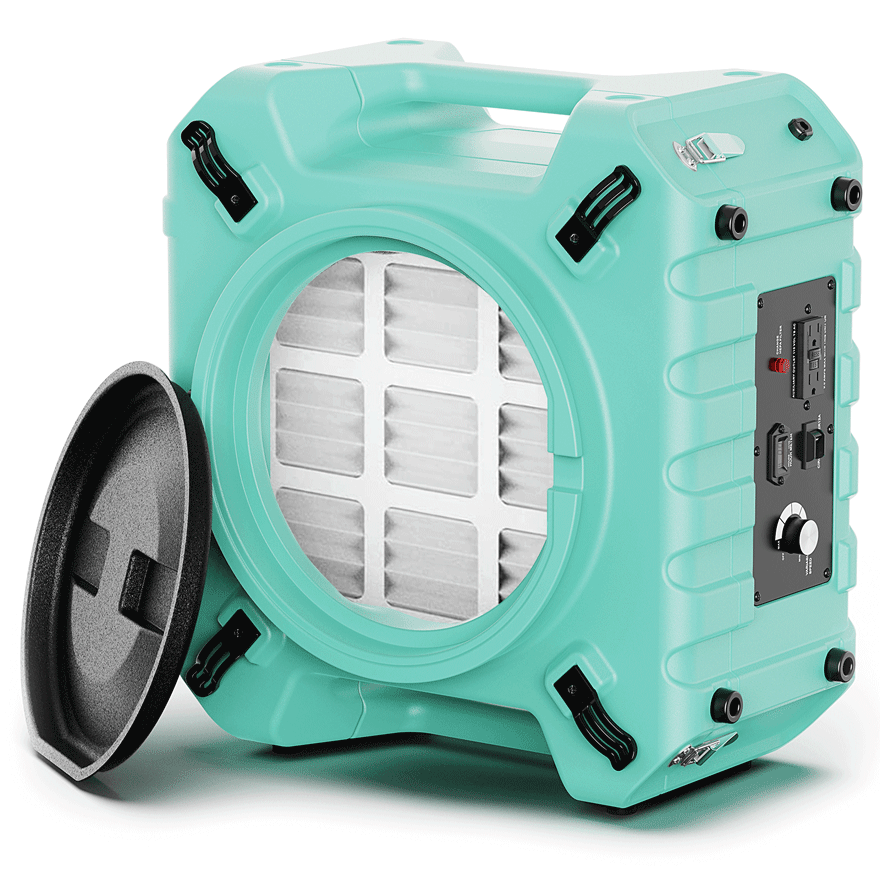

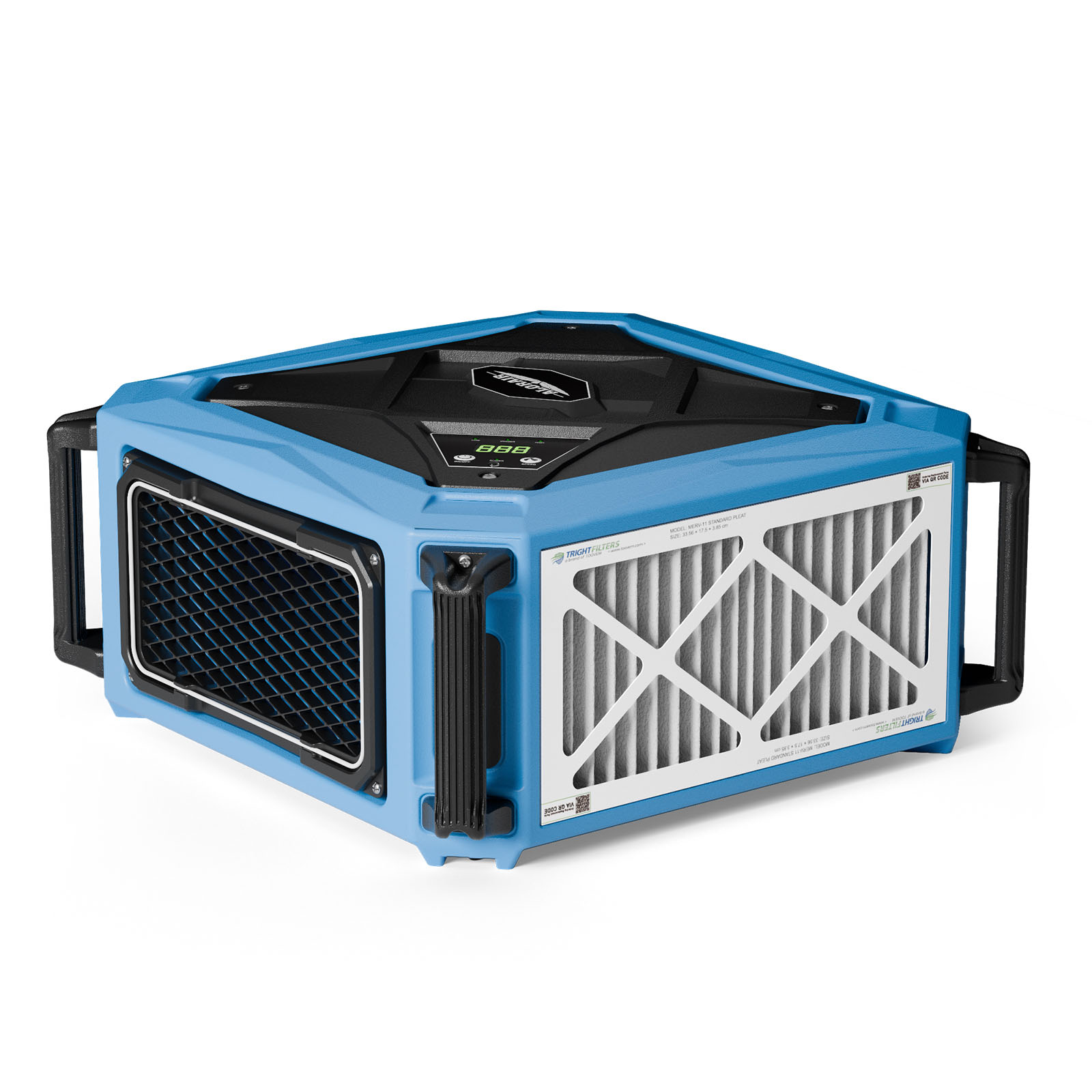

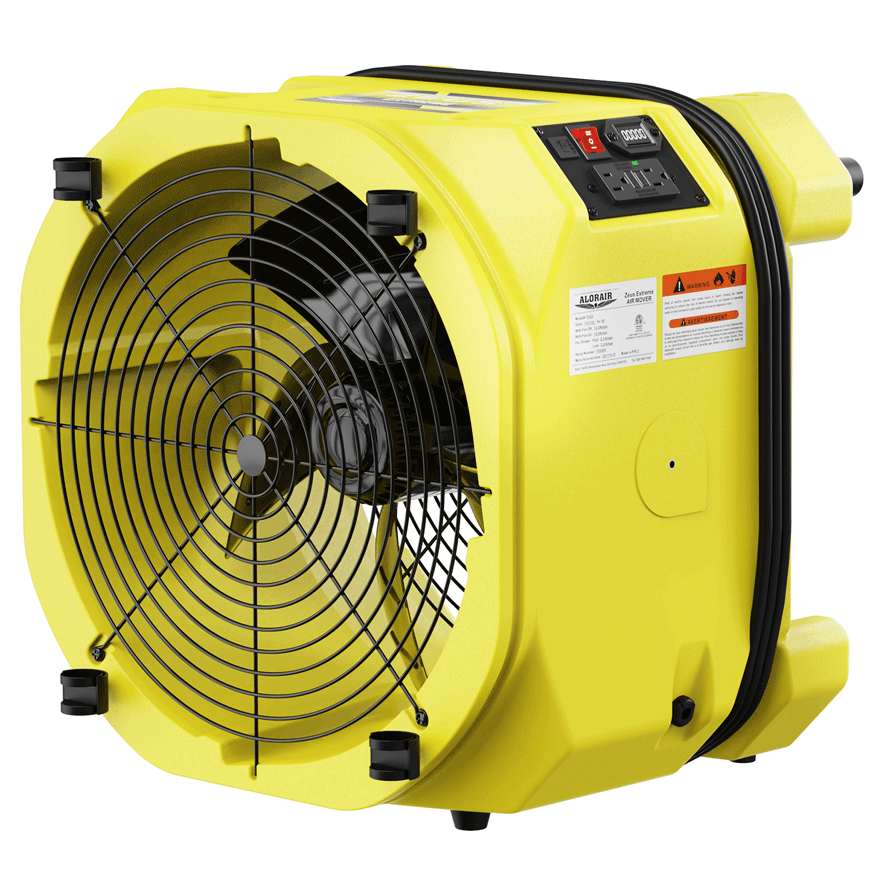

AlorAir commercial dehumidifier has Energy Star certified and C-ETL approved. Our dehumidifiers work by removing moisture from the atmosphere to achieve your ideal humidity level, and you don’t have to worry about condensation anymore. In addition, the machine is fitted with a high-efficiency rotor that sucks away humidity at record speed. The dehumidification system can be connected to the HVAC system to keep air flowing when dry air is blown where it is needed. And we offer a high-quality dehumidifier with low energy consumption. It is designed with simplicity but delivers impressively. You can disassemble the device and put it back together with ease. The equipment has been tested and proved to be working as a combination of expertise, innovation, and sturdiness. And it uses the rare earth alloy Tube Evaporator. They offer suitable protection against corrosion and other effects from unknown elements.

.jpg)

.jpg)

.jpg)

.jpg)

.HDi90.png)

.HD90.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-.jpg)

.jpg)

.jpg)

.jpg)

Exclusive offers

promotions

Exclusive offers

promotions